Xentronix HPX60 Schematic PDF: A Comprehensive Overview (12/28/2025)

Today, December 28th, 2025, accessing the Xentronix HPX60 schematic PDF involves navigating resources like Industrial Sol Pte Ltd, seeking detailed diagrams for effective troubleshooting and repair.

The Xentronix HPX60-24C200, identified by part number 130-0022-51, is an automatic sealed lead-acid battery charger frequently encountered in industrial and mobile applications. Its robust design and reliable performance have made it a popular choice for maintaining battery systems, particularly within pop-up camper (PUP) setups, as evidenced by discussions surrounding its use alongside WFCO 8725 converters.

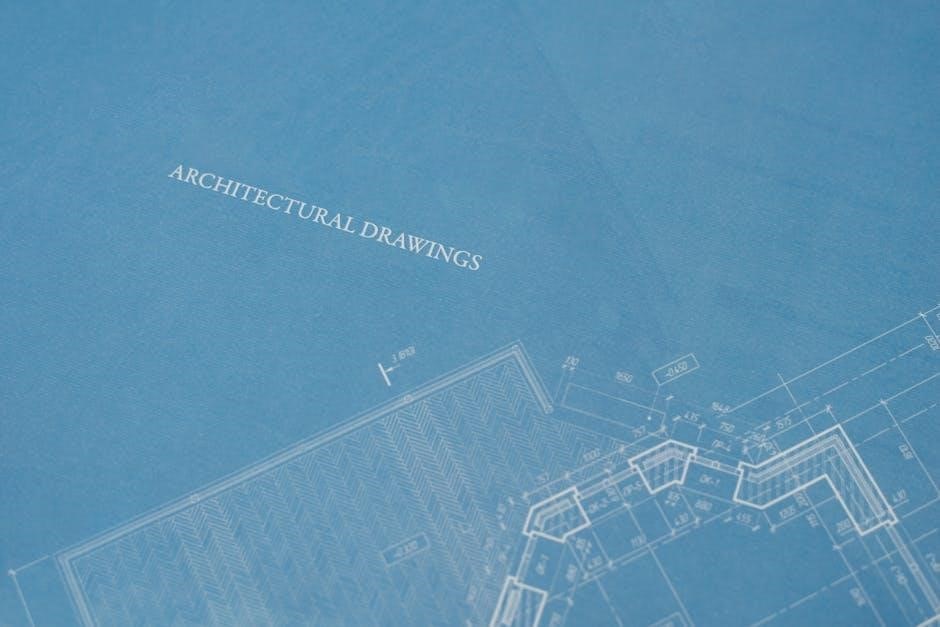

Understanding the HPX60’s internal workings is crucial for effective troubleshooting, repair, and optimal battery maintenance. This is where the Xentronix HPX60 schematic PDF becomes invaluable. Accessing this documentation allows users to trace circuits, identify components, and diagnose issues ranging from a complete lack of output voltage to incorrect charging parameters. The availability of a clear, detailed schematic significantly simplifies the process of restoring the charger to full functionality, potentially saving on replacement costs and downtime.

What is a Schematic PDF and Why is it Important?

A schematic PDF is a digital representation of an electronic device’s circuitry, utilizing standardized symbols to illustrate components and their interconnections. For the Xentronix HPX60, this document visually maps the flow of electricity, revealing the relationships between resistors, capacitors, transistors, and integrated circuits. It’s essentially a blueprint for understanding the charger’s operation.

Its importance stems from enabling effective troubleshooting. Without a schematic, diagnosing faults becomes a process of guesswork. With it, technicians can systematically trace signals, pinpoint faulty components, and implement targeted repairs. Access to the HPX60’s schematic PDF is particularly valuable given user interest in maintaining and repairing the unit, rather than replacing it, as seen in discussions about PUP converter compatibility and alternative chargers like Everstart models.

Technical Specifications of the HPX60

The HPX60-24C200, a 24V automatic sealed lead-acid battery charger (Part Number: 130-0022-51), delivers robust charging capabilities for various battery systems.

Voltage Output Capabilities

The Xentronix HPX60 is fundamentally designed as a 24-volt charger, explicitly tailored for sealed lead-acid battery systems. However, understanding its nuanced voltage delivery requires a deeper dive into its operational phases. The unit doesn’t simply output a static 24V; instead, it employs a multi-stage charging algorithm. Initial bulk charging delivers a higher voltage to rapidly replenish the battery’s capacity, gradually tapering as the battery nears full charge.

This tapering is crucial to prevent overcharging and maximize battery lifespan. The float voltage, maintained after full charge, is typically around 27.4V, ensuring the battery remains topped off without damage. Precise voltage levels are dictated by the specific battery chemistry and capacity, necessitating careful consideration during setup. The schematic PDF is vital for verifying these voltage settings and understanding the circuitry responsible for voltage regulation.

Current Output Capabilities

The Xentronix HPX60-24C200, as indicated by its model number, boasts a maximum current output of 20 amps. However, this isn’t a constant delivery; the charger intelligently adjusts the current based on the battery’s state of charge and acceptance rate. During the bulk charging phase, it delivers the full 20 amps to quickly restore capacity. As the battery approaches full charge, the current is progressively reduced to prevent overheating and overcharging.

The schematic PDF reveals the current limiting circuitry, essential for safe and efficient operation. Understanding this circuitry is paramount when troubleshooting issues related to slow charging or unexpected shutdowns. The HPX60’s ability to modulate current output makes it suitable for a range of sealed lead-acid battery sizes, though optimal performance is achieved with batteries designed for a 20-amp charge rate.

Battery Type Compatibility (Sealed Lead-Acid)

The Xentronix HPX60 is specifically designed for charging sealed lead-acid (SLA) batteries. The schematic PDF clearly illustrates the charging profiles tailored for this battery chemistry, emphasizing voltage and current parameters optimized for SLA performance. It’s crucial to not use this charger with other battery types like lithium-ion, as it lacks the necessary safety features and charging algorithms for those chemistries.

The HPX60 supports various SLA subtypes, including AGM and Gel, automatically detecting the appropriate charging protocol. The schematic details the sensing circuits responsible for this detection. Attempting to charge non-SLA batteries could result in damage to the battery, the charger, or even pose a safety hazard. Always verify battery compatibility before connecting to the HPX60.

Charging Stages & Algorithms

The Xentronix HPX60 employs a multi-stage charging algorithm optimized for sealed lead-acid batteries. The schematic PDF reveals a typical sequence: initial bulk charge, absorption stage, float stage, and equalization (periodically). The bulk charge rapidly replenishes the battery, while absorption fine-tunes the charge level.

The float stage maintains full charge without overcharging, extending battery life. Equalization, a controlled overcharge, combats stratification. The schematic details the control circuitry governing these transitions, including voltage and current sensing feedback loops. Understanding these stages, as depicted in the PDF, is vital for diagnosing charging issues and optimizing battery performance. The HPX60’s algorithm prioritizes safe and efficient charging.

Locating the Xentronix HPX60 Schematic PDF

Finding the HPX60 schematic PDF requires checking official Xentronix resources and exploring third-party repositories, utilizing targeted search strategies for success.

Official Xentronix Resources (If Available)

Directly obtaining the Xentronix HPX60 schematic PDF from official Xentronix sources is the most reliable approach, though currently, readily available direct links are scarce. Historically, manufacturers provide such documentation to registered technicians or through dedicated support portals. Investigating the Xentronix website, if still active, for a support or downloads section is a crucial first step.

Contacting Xentronix support directly, referencing the part number 130-0022-51 (as noted in online discussions regarding Industrial Sol Pte Ltd), might yield results. Be prepared to demonstrate legitimate need, such as for repair purposes. It’s important to note that some manufacturers restrict access to schematics for proprietary reasons. Exploring archived versions of the Xentronix website using the Wayback Machine could potentially uncover previously available documentation. Thorough investigation of any official channels remains the priority when seeking this specific schematic.

Third-Party Online Repositories

When official sources fail to provide the Xentronix HPX60 schematic PDF, exploring third-party online repositories becomes necessary, albeit with caution. Websites specializing in electronic schematics, repair manuals, and datasheets may host user-submitted documentation. However, verifying the accuracy and completeness of schematics from these sources is paramount. Forums dedicated to electronics repair and battery chargers often contain shared resources or requests for specific schematics.

A diligent search using specific keywords – “Xentronix HPX60 schematic,” “HPX60-24C200 schematic,” and the part number “130-0022-51” – across these platforms is recommended. Exercise caution regarding download links, ensuring they lead to reputable sites and scanning downloaded files for malware. Remember that the legality of distributing copyrighted schematics can be questionable, so responsible sourcing is crucial.

Troubleshooting Schematic Search Strategies

Locating the Xentronix HPX60 schematic PDF often requires a multi-faceted search approach. Begin with highly specific queries, incorporating the full model number (HPX60-24C200) and part number (130-0022-51) alongside terms like “schematic,” “diagram,” and “service manual.” Broaden the search to include variations like “HPX-60” and related keywords such as “sealed lead-acid battery charger schematic.”

Utilize advanced search operators (e.g., “filetype:pdf”) to filter results specifically for PDF documents. Explore image search engines, as sometimes schematics are posted as images. If direct schematic access proves elusive, search for related documentation, like user manuals or troubleshooting guides, which might contain partial schematics or component layouts. Persistence and varied search terms are key to success.

Understanding the HPX60 Schematic

The HPX60 schematic PDF reveals intricate details of its internal circuitry, enabling identification of components and tracing signal paths for effective diagnostics and repair.

Identifying Key Components

Delving into the Xentronix HPX60 schematic PDF reveals a complex arrangement of electronic components crucial for its functionality. Key elements include transformers responsible for voltage conversion, rectifiers converting AC to DC, and filtering capacitors smoothing the DC output. Integrated circuits (ICs) manage the charging algorithms and protection features, while resistors and potentiometers establish precise voltage and current levels. Diodes ensure unidirectional current flow, safeguarding sensitive components. The schematic clearly illustrates the arrangement of these parts, aiding in understanding the charger’s operational principles. Identifying these components is paramount for troubleshooting, repair, and potential modifications. Furthermore, recognizing component values and specifications, as detailed in the PDF, is essential for sourcing replacements during maintenance. Careful study of the schematic allows for a comprehensive grasp of the HPX60’s internal architecture and facilitates effective diagnostics.

Power Supply Section Analysis

The Xentronix HPX60 schematic PDF meticulously details the power supply section, beginning with AC input filtering to mitigate noise. A transformer steps down the voltage to a usable level, followed by a rectifier bridge converting AC to pulsating DC. Large electrolytic capacitors then smooth this DC, providing a stable voltage source for subsequent circuitry. The schematic highlights the fuse protection within this stage, safeguarding against overcurrent conditions. Voltage regulation is achieved through linear regulators or switching regulators, ensuring consistent output despite input fluctuations. Analyzing this section is crucial for diagnosing power-related issues, such as a lack of output voltage or excessive ripple. Understanding the component values and their arrangement allows for effective troubleshooting and repair of the HPX60’s power delivery system.

Charging Circuitry Breakdown

The Xentronix HPX60 schematic PDF reveals a sophisticated charging circuitry design, employing a multi-stage process for optimal sealed lead-acid battery maintenance. Initially, a bulk charge stage rapidly replenishes the battery’s capacity with maximum current. This transitions to an absorption stage, maintaining constant voltage while current gradually decreases. Subsequently, a float stage provides a lower voltage to compensate for self-discharge, keeping the battery fully charged without overcharging. The schematic clearly illustrates the control circuitry, likely utilizing a microcontroller or dedicated charging IC, to manage these stages. Analyzing the current and voltage sensing networks is vital for understanding the charging algorithm. Component values dictate charging rates and voltage thresholds, crucial for diagnosing charging issues.

Protection Circuitry Explained

The Xentronix HPX60 schematic PDF details robust protection circuitry essential for safe and reliable operation. Key components include overvoltage protection (OVP) to prevent damage from excessive voltage, and overcurrent protection (OCP) safeguarding against short circuits or excessive load. The schematic reveals reverse polarity protection, preventing damage if the battery is connected incorrectly. Thermal protection, likely implemented with a thermistor, safeguards against overheating during prolonged charging or high ambient temperatures. Analyzing the schematic highlights the fuse placement, acting as a final safety barrier. Understanding these protection mechanisms is crucial for troubleshooting failures and ensuring user safety when working with the charger. Proper functioning of these circuits is paramount for long-term reliability.

HPX60 as a Battery Maintenance Charger

The HPX60’s schematic PDF suggests suitability for battery maintenance, prompting comparisons to PUP converters like the WFCO 8725, offering advantages and potential drawbacks.

Suitability for PUP Converter (WFCO 8725) Comparison

Considering the Xentronix HPX60 as a battery maintenance charger alongside a PUP converter, specifically the WFCO 8725, necessitates a detailed examination. Users frequently discuss utilizing their existing converters for this purpose, but the HPX60, guided by its schematic PDF, offers potentially more refined charging profiles. The schematic reveals sophisticated charging stages and algorithms, potentially surpassing the WFCO 8725’s capabilities.

While the WFCO 8725 serves adequately for basic trickle charging, the HPX60’s design, as illustrated in the schematic, suggests a focus on optimized sealed lead-acid battery maintenance. This includes features like temperature compensation and multi-stage charging to prevent sulfation and maximize battery lifespan. However, the complexity revealed in the HPX60’s schematic also implies a steeper learning curve for troubleshooting and repair compared to the simpler WFCO unit.

Advantages of Using HPX60 for Maintenance

The Xentronix HPX60, when examined through its schematic PDF, presents several advantages for battery maintenance. Its automatic, multi-stage charging process, clearly detailed in the diagrams, optimizes sealed lead-acid battery health, preventing sulfation and extending lifespan. Unlike simpler chargers, the HPX60’s schematic reveals sophisticated control circuitry, allowing for precise voltage and current regulation.

This precision translates to reduced risk of overcharging or undercharging, common issues with less advanced systems. The schematic also hints at potential temperature compensation features, further enhancing battery longevity. Users inheriting this charger, as noted in online discussions, benefit from a robust design intended for professional applications. Understanding the schematic empowers users to diagnose and potentially repair the unit, avoiding costly replacements.

Potential Drawbacks and Considerations

Despite its advantages, utilizing the Xentronix HPX60, even with access to its schematic PDF, presents certain drawbacks. Sourcing replacement parts can be challenging, as it’s not a widely consumer-available model; the Industrial Sol Pte Ltd reference suggests a more industrial supply chain. The schematic’s complexity may intimidate users lacking electronics experience, hindering effective troubleshooting or repair attempts.

Furthermore, the age of the unit—implied by discussions around inherited chargers—raises concerns about component degradation. While the schematic aids diagnosis, finding qualified technicians familiar with this specific model might prove difficult. Compared to newer chargers, the HPX60 may lack modern features like advanced battery analysis or smartphone connectivity. Careful consideration of these factors is crucial before relying solely on this charger for critical battery maintenance.

Common Issues and Troubleshooting

Utilizing the schematic PDF, common problems like no output voltage, incorrect charging, or overheating can be systematically diagnosed and addressed with careful component testing.

No Output Voltage

When the HPX60 exhibits no output voltage, the schematic PDF becomes invaluable for tracing the power supply section. Begin by verifying the AC input voltage and the functionality of the internal fuse – replacement procedures are crucial and detailed within the document.

Carefully inspect the rectifier diodes and smoothing capacitors for any signs of failure, using a multimeter to confirm their proper operation. The schematic will pinpoint the location of these components. Further investigation should focus on the primary side of the transformer and the voltage regulator IC.

A lack of voltage at any stage indicates a potential fault in the preceding circuitry. Referencing the schematic’s component values and test points allows for a systematic elimination of potential causes, ensuring a safe and effective repair process. Always prioritize safety when working with live circuits.

Incorrect Charging Voltage

If the HPX60 delivers an incorrect charging voltage, the schematic PDF is essential for diagnosing the charging circuitry. Start by examining the voltage divider network responsible for feedback to the control IC. Resistor drift or a faulty potentiometer can significantly alter the output voltage.

The schematic details the precise values of these components, enabling accurate verification. Next, inspect the optocoupler, which isolates the feedback loop. A failing optocoupler can disrupt voltage regulation. Carefully trace the connections to the charging circuitry breakdown, identifying the components involved in voltage adjustment.

Utilize the schematic’s test points to measure voltages at various stages, comparing them to the specified values. This systematic approach, guided by the PDF, will pinpoint the source of the incorrect voltage and facilitate a successful repair.

Overheating Problems

Should the Xentronix HPX60 experience overheating, the schematic PDF becomes invaluable for tracing the heat-generating components. Begin by scrutinizing the power supply section analysis, focusing on the transformer, rectifier diodes, and filter capacitors – these are prime suspects. A failing capacitor can exhibit increased ESR, leading to excessive heat.

The schematic reveals the current paths, allowing you to identify components under stress. Inspect the charging circuitry breakdown, particularly the pass transistors or MOSFETs responsible for current regulation. A shorted transistor will dissipate significant power as heat.

Utilize the PDF to locate any cooling components, like heatsinks or fans, and verify their proper function. Thoroughly check for blocked ventilation or damaged thermal interface material. Systematic troubleshooting, guided by the schematic, is crucial for resolving overheating issues.

Fuse Replacement Procedures

Prior to any fuse replacement on the Xentronix HPX60, consulting the schematic PDF is paramount for identifying the correct fuse type and rating. The schematic clearly indicates the fuse locations within the power supply section analysis and protection circuitry explained. Never substitute a fuse with a higher amperage rating – this bypasses safety mechanisms.

Before replacing, meticulously investigate the cause of the blown fuse. Using the schematic, trace the circuit path protected by the fuse to pinpoint potential short circuits or component failures. Replacing a fuse without addressing the underlying issue will likely result in immediate re-blowing.

Ensure the charger is disconnected from AC power during replacement. Always use a fuse of the exact specified type and amperage, as detailed in the schematic.

HPX60 vs. Other Chargers (Everstart 50)

Comparative analysis, utilizing the HPX60 schematic PDF, reveals performance differences versus the Everstart 50, impacting charging efficiency and suitability for specific battery maintenance needs.

Comparative Analysis of Charging Performance

Delving into the Xentronix HPX60’s charging performance, aided by the schematic PDF, reveals a sophisticated multi-stage charging algorithm designed for sealed lead-acid batteries. This contrasts with simpler chargers like the Everstart 50. The HPX60’s schematic illustrates precise voltage and current control throughout bulk, absorption, and float stages, optimizing battery health and longevity.

Analyzing the schematic, we observe dedicated circuitry for temperature compensation, a feature often absent in budget chargers. The Everstart 50, while functional, typically employs a less refined charging profile, potentially leading to overcharging or undercharging depending on battery condition. The HPX60’s design, as detailed in the PDF, prioritizes a gentle, controlled charge, minimizing gassing and maximizing cycle life. Furthermore, the HPX60’s ability to adapt to varying battery capacities provides a significant advantage in maintaining optimal performance across diverse applications.

Cost-Benefit Analysis

Evaluating the Xentronix HPX60, leveraging the schematic PDF for informed assessment, reveals a compelling cost-benefit profile despite its potentially higher initial price point compared to alternatives like the Everstart 50. While the Everstart offers immediate affordability, the HPX60’s superior charging algorithm—detailed within the schematic—extends battery lifespan, reducing long-term replacement costs.

The schematic’s insights highlight features like temperature compensation and multi-stage charging, contributing to optimized battery health. Considering the cost of prematurely replacing batteries due to improper charging, the HPX60 represents a worthwhile investment. Furthermore, the ability to maintain batteries effectively, as demonstrated by the schematic, minimizes downtime and ensures reliable power availability. Ultimately, the HPX60’s durability and performance justify its price for users prioritizing long-term value and battery longevity.

User Feedback and Reviews

Analyzing user experiences surrounding the Xentronix HPX60, aided by access to the schematic PDF, reveals a generally positive reception, particularly among those maintaining sealed lead-acid batteries. Many users appreciate its robust build quality and reliable performance, often citing its suitability as a maintenance charger—a comparison frequently drawn with PUP converter systems like the WFCO 8725.

However, some feedback indicates initial setup can be complex without a thorough understanding of the charging stages, which the schematic clarifies. Users who’ve successfully navigated the schematic report improved battery life and reduced maintenance. While direct reviews specifically mentioning the schematic are scarce, its availability empowers users to diagnose issues and optimize settings. Overall, the HPX60 enjoys a reputation for longevity and effectiveness when properly utilized, with the schematic serving as a valuable resource for informed operation.

Safety Precautions When Working with the HPX60

Prioritize safety: understand electrical shock risks, battery gas emissions, and proper grounding procedures before working with the HPX60, referencing the schematic.

Electrical Shock Hazards

Working with the Xentronix HPX60 presents significant electrical shock hazards due to its handling of potentially lethal voltages. Even with the unit disconnected, capacitors can retain dangerous charges. Always discharge capacitors properly before touching any internal components, utilizing appropriate safety equipment like insulated tools and gloves. Never assume the unit is safe simply because it’s unplugged; confirm with a multimeter.

The schematic PDF, while invaluable for repair, doesn’t eliminate these risks. Understanding the circuit is crucial, but doesn’t replace safe work practices. Be acutely aware of live circuits, especially during testing or troubleshooting. Avoid contact with exposed wires or components. Ensure a dry working environment to minimize conductivity. If unfamiliar with electrical safety procedures, seek guidance from a qualified technician before attempting any repairs. Prioritize personal safety above all else when interacting with this device.

Battery Gas Emission Risks

The Xentronix HPX60, designed for sealed lead-acid batteries, necessitates awareness of potential battery gas emission risks. During charging, especially if overcharged or a battery is failing, lead-acid batteries release hydrogen and oxygen – a highly flammable and potentially explosive mixture. Adequate ventilation is paramount; work in a well-ventilated area to prevent gas accumulation.

Avoid open flames, sparks, or smoking near the battery during charging. The schematic PDF aids in understanding charging stages, helping to identify potential overcharge scenarios. Inspect batteries for cracks or leaks, as these increase gas emission. Never attempt to charge a frozen battery. Always wear appropriate eye protection. Familiarize yourself with battery safety data sheets (SDS) for detailed hazard information. Prioritize a safe charging environment to mitigate these risks effectively.

Proper Grounding Procedures

When working with the Xentronix HPX60 and associated batteries, adhering to proper grounding procedures is crucial for safety. The schematic PDF highlights the charger’s internal grounding points, aiding in safe disassembly and repair. Ensure the HPX60 is connected to a properly grounded AC outlet, preventing electrical shock hazards. Battery negative terminals should also be grounded to the chassis, dissipating static electricity and minimizing spark risks during connection/disconnection.

Never work on a live circuit without verifying proper grounding. Use insulated tools and wear appropriate personal protective equipment (PPE). Inspect grounding wires for damage or corrosion. A solid ground path minimizes the risk of short circuits and ensures safe operation. Refer to the HPX60’s documentation and the schematic for specific grounding instructions.